Slip Casting Training for Ionix Advanced Technologies

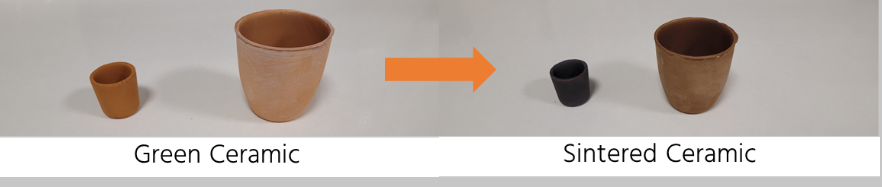

Slip casting is the process of producing green ceramic bodies from a ceramic slurry, or slip, using a plaster mould to cast the desired shape. This has an advantage over traditional ceramic processing in that this allows production of tapered or spherical shapes without significant post processing.

Dr Peter Cowin of Ionix attended a day of training, funded by PMI Trust Fund, at Almath Ltd. The training at Almath provided a strong grounding in the basics of the slip casting process, including slip preparation, mould and former production, slip casting, demoulding and post processing.

Slip casting training allows Ionix to apply this processing method to new piezoelectric materials, improving our current processing capability to produce new architectures and novel structures. For example, this process can be applied to the production of hemispherical parts, which are used in HIFU (High-Intensity Focused Ultrasound) applications.